1、 What is intrinsically safe electrical equipment?

By limiting various parameters of electrical equipment circuits or taking protective measures to limit the spark discharge energy and thermal energy of the circuit, the electrical sparks and thermal effects generated under normal operation and specified fault conditions cannot ignite the explosive mixture in the surrounding environment, thus achieving electrical explosion-proof. The circuit of this electrical equipment itself has explosion-proof performance, which means it is inherently safe, hence it is called intrinsic safety type. Electrical equipment that uses intrinsic safety circuits is called intrinsic safety electrical equipment.

2、 Explosion proof principle of intrinsically safe electrical equipment

The intrinsic safety explosion-proof type is that all circuits inside the equipment are regulated under standard conditions(Including normal operation and specified fault conditions)Any electric spark or thermal effect generated below cannot ignite the intrinsic safety circuit of the explosive gas environment specified by China National Nuclear Corporation. Intrinsically safe type starts with limiting the energy in the circuit, reducing the potential spark energy to below the specified ignition energy of the gas mixture through reliable control of circuit parameters, and limiting the surface heating temperature of wires and components to below the specified ignition temperature of the gas mixture.

3、 Interpretation of intrinsically safe explosion-proof grade

1“ia”Grade electrical equipment is an inherently safe type of electrical equipment that operates normally and cannot ignite under any combination of two fault conditions.“ia”The type of instrument is suitable for0District1District and2District.

2“ib”Grade electrical equipment is an inherently safe type of electrical equipment that operates normally and cannot cause ignition under a fault condition.“ib”The type of instrument is suitable for1District and2District.

3“ic”Grade electrical equipment does not consider fault conditions and is suitable for2District.

4、 The main measures for intrinsic safety explosion-proof are:

1. Voltage and current limitations of circuits;

2. Limitations on capacitors and inductors in circuits;

3. Isolation between intrinsic safety circuits and non intrinsic safety circuits;

4. Requirements for reliable components and assemblies;

5. Regulations on safety barriers;

6. Fault analysis and testing regulations, etc.

5、 Standards applicable to intrinsically safe electrical equipment:

1GB/T 3836.4-2021Explosive Environment4Part: Made of intrinsic safety type“i”Protected equipment

2IEC60079-11:2023Explosive Environment11Part: Made of intrinsic safety type“i”Protected equipment

6、 Characteristics and Scope of Application of Intrinsic Safety Electrical Equipment

Due to the inherent safety of the circuits in intrinsically safe electrical equipment, sparks, arcs, and thermal energy generated will not ignite explosive mixtures in the surrounding environment. Therefore, intrinsically safe electrical equipment does not require specialized explosion-proof enclosures, which can reduce the size and weight of the equipment and simplify its structure. At the same time, the transmission lines of intrinsically safe electrical equipment can be made of rubber wires and bare wires, which can save a lot of cables. Therefore, intrinsic safety electrical equipment has the characteristics of safety and reliability, simple structure, small size, light weight, low cost, and easy manufacturing and maintenance, making it an ideal explosion-proof electrical equipment. However, due to the maximum output power of intrinsically safe electrical equipment being25WLeft and right, therefore the scope of use is limited. At present, intrinsically safe electrical equipment is mainly used for communication, monitoring, signal and control systems, as well as instruments, meters, etc.

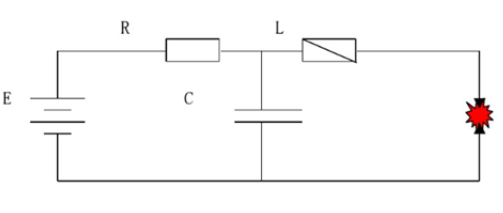

surface1Schematic diagram of intrinsic safety circuit

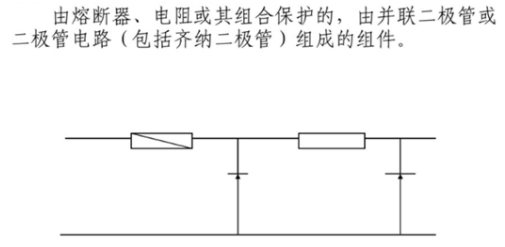

surface2Inherent safety component - Zener safety barrier

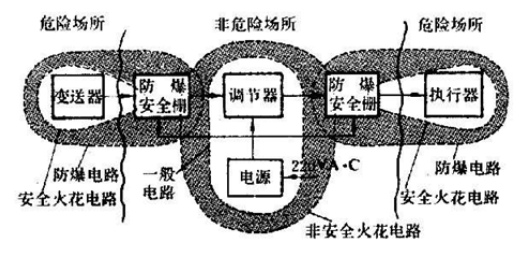

surface3Structure diagram of intrinsic safety system

The copyright of this article belongs to Zhongnuo Testing. Plagiarism and theft will be pursued, and reprinting must indicate the original source.

|

||||||

|

||||||