Dust explosion refers to a chemical reaction in which combustible dust mixes with air in a confined space to form a dust cloud. Under the action of an ignition source, the resulting dust air mixture rapidly burns and causes a sudden increase in temperature and pressure. Dust explosions often occur in production and processing sites accompanied by aluminum powder, zinc powder, aluminum processing grinding powder, various plastic powders, intermediates of organic synthetic drugs, wheat flour, sugar, sawdust, dyes, bakelite ash, milk powder, tea powder, tobacco powder, coal dust, plant fiber dust, etc.

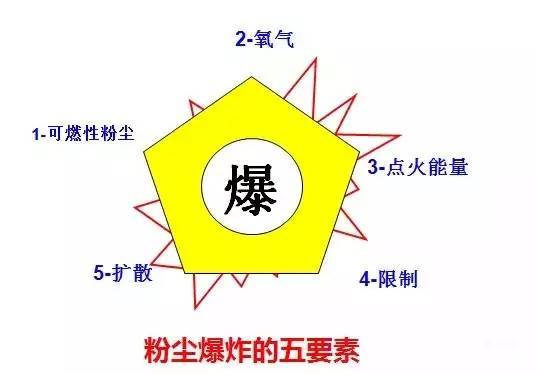

From the perspective of the formation of dust explosions, combustible substances, air, and ignition sources are the three basic conditions for the occurrence of explosion events, namely the three elements of explosion.

Can dust explode? The dust explosion screening device is mainly used for preliminary identification of whether dust samples have explosiveness, and can be used for on-site determination of dust explosiveness.

(1) Judgment criteria: VDI2263.1-1990

(2) Does a sustained flame occur under the condition of 4J ignition energy in the explosion screening device. If dust cannot be ignited in Hartmann, a more powerful ignition source is required for testing in a larger container (1m ³ can).

(3) Judgment criteria: VDI2263.1-1990

(4) The pressure generated under the condition of 10kJ ignition energy in a 1 m ³ device is 0.5bar higher than the initial test pressure.

Dust ignition sensitivity

Dust and minimum ignition energy test: Determine whether electrical equipment discharge can ignite explosive dust and air mixtures. The minimum ignition energy is used to evaluate the corresponding ignition hazards caused by electrical or electrostatic discharge, and ultimately determine whether electrical equipment is suitable for installation in places where explosive dust is present.

Minimum ignition temperature test for dust: Control the surface temperature of the equipment to prevent dust from igniting in the dust layer, providing a basis for selecting explosion-proof electrical equipment for dust.

The minimum ignition temperature test provides the following information:

The ignition sensitivity caused by possible hot surfaces in the dryer, the ignition sensitivity caused by overheating of bearings and other mechanical components, the ignition sensitivity caused by friction ignition, and the maximum allowable outer surface temperature of electrical equipment.

This article is copyrighted by Shenzhen Zhongnuo Testing Technology Co., Ltd. Plagiarism, theft, and reproduction are strictly prohibited.

|

||||||

|

||||||